Mainly used to crush

Coal for circulating fluidized bed boiler

Coking coal for coke even

Coal, coke, limestone, dolomite, lime and etc. for sinter plant

All kinds of low and medium hardness ore, such as iron ore, phosphate rock and etc.

Main features and advantages

Advanced design and various functions

Higher efficiency and reliable operation

Excellent uniformity of product size and low fine grain ratio

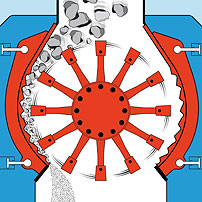

After entering the crushing cavity, the feed material is grasped by the rotating beater heads and then thrown against the grinding face at high speed to be crushed and again rebound to beater heads. The material is gradually crushed in a course of dash and inter-collision repeatedly and discharged out of the end of grinding face.

Product size is determined by rotation speed of the rotor, weight of hammers and gap between the rotor and the grinding wall.

-

Standard type / Heavy type

Normally, standard type of rotor and grinding faces are adopted for brittle material, and heavy type for hard material (limestone, iron ore and etc).

-

Drive mode

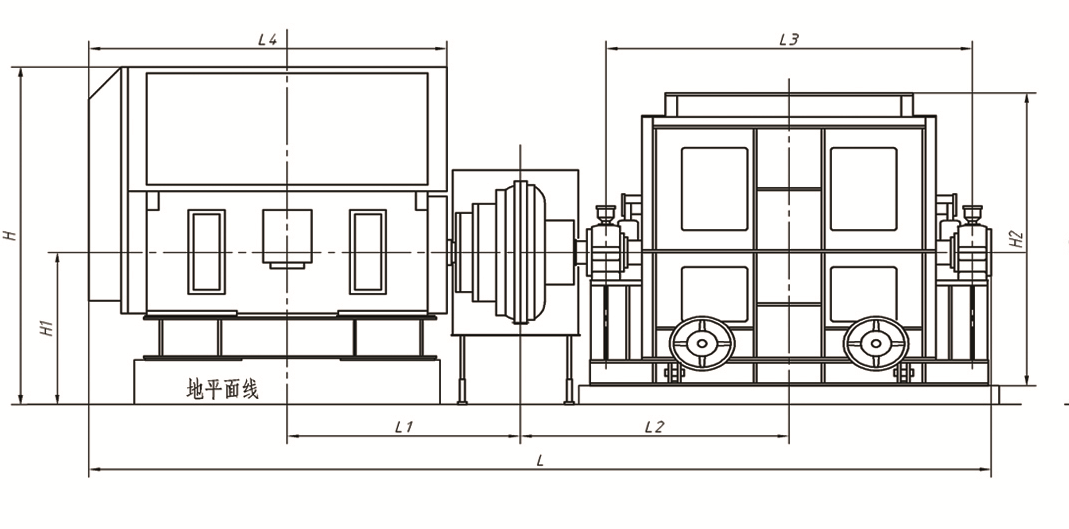

Direct-coupling: Rotor shaft is driven by motor through fluid coupling with motor and mill arranged a straight line.

Parallel: Rotor shaft is driven by motor through big and small pulley besides coupling with motor and mill laid in parallel.

-

Reversible / Non-reversible

Reversible impact hammer mill is equipped with grinding faces at both sides, allowing reversible operation and thus utilization of heads and grinding faces at both sides. As the rotor of the non-reversible hammer mill operates in single-direction, the heads have to be reversed for use after being worn out on one side.

-

Shock absorption device

E-motor and mill are fitted on a whole plate form, fitted with shock absorption units for lowering down motional load and noise effectively.

-

Bearing temperature & vibration detection device

Bearing temperature and vibration amplitude can be detected and displayed at local instrument box with signals transmitted to central control room.

-

Bearing lubrication device

Automatic oil or grease lubrication unit is adopted for bearings to get continuous and full lubrication and maintenance.

-

Fluidized bed drying system

Fluidized bed drying system, integrating classifying, drying and crushing as a whole, can modify moisture while crushing selectively to meet process requirement.

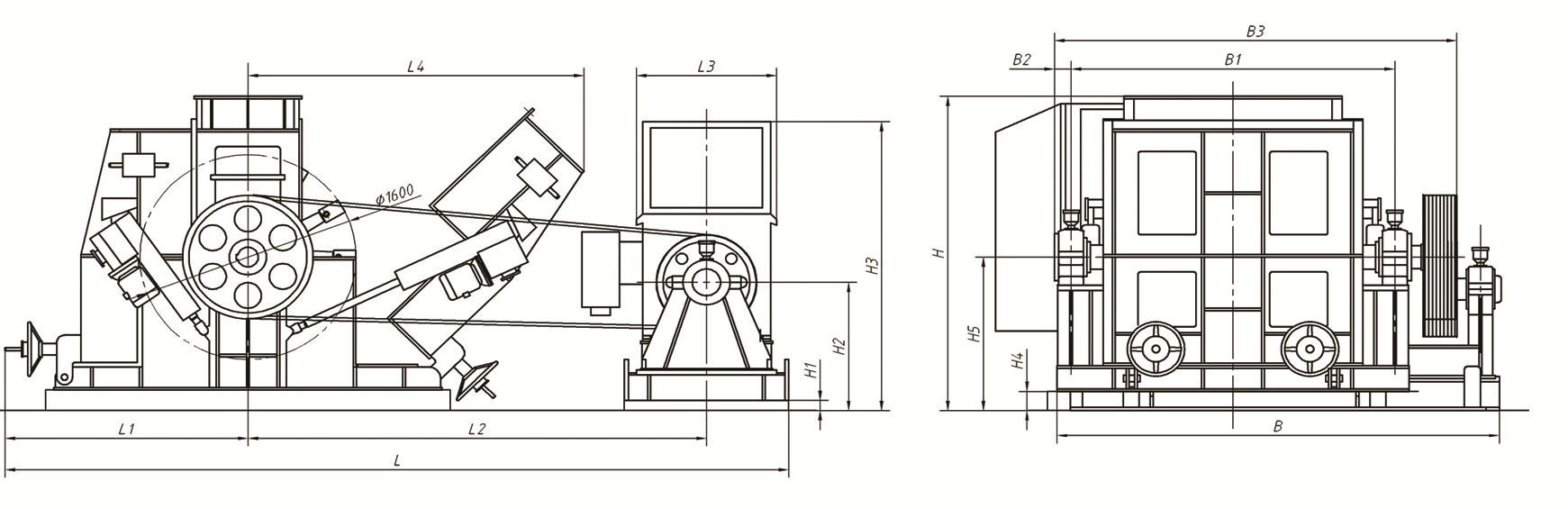

PCFK series of Reversible Impact Hammer Mill consists of rotor, crushing plate and adjusting units, housing, base frame, and drive unit.

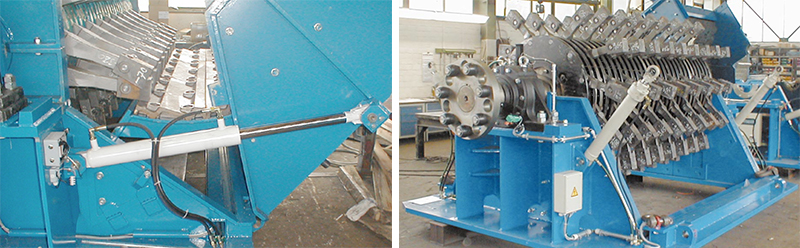

1. The left and right frames are symmetry to ensure the motor is reversible. Grinding faces are installed at both sides of the frame to make full use of both sides of hammer head. The left and right housings can be opened up upto 45°max through hydraulic device to facilitate maintenance.

2. Main shaft and hub discs are forged with quality steel and assembled in octagon structure to ensure that the working portion of main shaft is in uniform stresses and balance of the rotor, which also facilitates maintenance.

3.The flexible connection of beater arms with heads can ensure that hammer mill is sturdy enough against the intrusion of foreign hard matter.

4.Hammer heads are arranged in spiral for stable load and good crushing effect. The arms and heads are weighed by pairs to ensure exact balancing of the rotor. The arms are forged with quality steel and the heads are made of high wear-resistant alloy cast.

5. Specially designed crushing plate are fitted on the grinding wall to guarantee the angle of incidence of the material against the grinding wall at nearly 90° for optimum crushing result. Gap between rotor and grinding wall can be adjusted to compensate wearing of grinding faces and change size of finished product.

|

Model no. |

Output (t/h) |

Feed size(mm) |

Output size(mm) |

Motor power(kw) |

Rotor diameter(mm) |

Rotor length(mm) |

|

PCFK1006 |

10-15 |

≤50/20 |

≤8/3 |

55 |

1000 |

600 |

|

PCFK1008 |

20-30 |

≤50/20 |

≤8/3 |

75 |

1000 |

800 |

|

PCFK1010 |

30-40 |

≤50/20 |

≤8/3 |

90 |

1000 |

1080 |

|

PCFK1012 |

50-60 |

≤50/20 |

≤8/3 |

132 |

1000 |

1240 |

|

PCFK1210 |

60-70 |

≤70/30 |

≤8/3 |

160 |

1200 |

1080 |

|

PCFK1212 |

80-90 |

≤70/30 |

≤8/3 |

185 |

1200 |

1240 |

|

PCFK1214 |

110-120 |

≤70/30 |

≤8/3 |

250 |

1200 |

1400 |

|

PCFK1414 |

130-150 |

≤70/30 |

≤8/3 |

280 |

1400 |

1400 |

|

PCFK1416 |

160-190 |

≤70/30 |

≤8/3 |

315 |

1400 |

1640 |

|

PCFK1612 |

140-160 |

≤80/30 |

≤8/3 |

355 |

1600 |

1240 |

|

PCFK1616 |

200-220 |

≤80/30 |

≤8/3 |

450 |

1600 |

1640 |

|

PCFK1618 |

250-280 |

≤80/30 |

≤8/3 |

630 |

1600 |

1800 |

|

PCFK1820 |

350-400 |

≤80/30 |

≤8/3 |

710 |

1800 |

2000 |

|

PCFK1825 |

500-550 |

≤80/30 |

≤8/3 |

800 |

1800 |

2500 |

LinkedIn

LinkedIn Twitter

Twitter Facebook

Facebook Instagram

Instagram YouTube

YouTube