VRM integrates grinding, drying, sorting and conveying, which greatly simplifies the process flow. Compared with the traditional ball mill, the vertical mill can significantly reduce energy consumption and metal wear, and bring considerable economic...

As a kind of high efficiency grinding equipment, vertical roller mill is widely used for grinding various materials with high requirements of fineness and energy efficiency.

The grindability is from easy grinding to difficult grinding, and the grinding

energy consumption is from 4kwh / T to 25kwh / T.

The moisture content of the material ranges from 1% to 25%.

From non abrasive materials to highly abrasive materials.

From non cohesive materials to highly cohesive materials.

Through continuous optimization of structure design, andI company has successfully applied vertical roller mill technology to the grinding system of the following materials, and has accumulated rich practical experience in mill design and grinding system engineering

Preparation and injection system of pulverized coal for blast furnace, rotary kiln

and hot blast stove

Anthracite and coke blending process

Grinding of cement raw materials and clinker

Grinding of granulated blast furnace slag

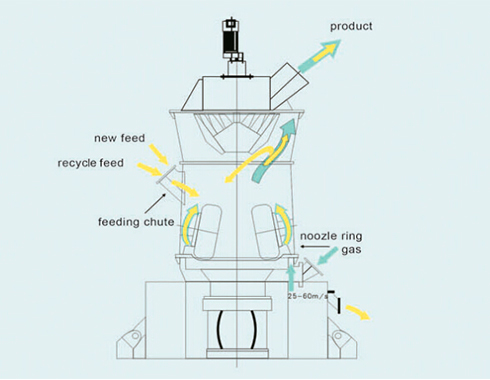

The material is fed into the center of the rotating grinding plate through the rotary feeder (or sealed weighing feeder) and the feeding trough, and the metal foreign matters are separated from the material before reaching the rotary feeder. Under the action of centrifugal force, the material diffuses to the annular grinding roller table of the grinding plate. After being rolled by the grinding roller loaded by the hydraulic elastic system, it further moves to the edge of the grinding plate. The hot air is evenly distributed around the grinding plate through the air ring, and the milled and to be ground materials are blown up by the air flow at the air ring and dried. During the rising process of the mill, due to the gravity separation, the coarse particles fall back to the grinding plate, and the fine particles are carried to the separator by the air flow.

With the help of the separator blade, the material is divided into coarse powder and fine powder. The coarse powder falls back to the grinding plate for regrinding, and the fine powder flows out of the mill along with the gas and is collected in the powder collecting device of the system, which is the qualified product.

-

Grinding mechanism

Feed material is ground between the rollers and the rotating table in the mill with vertical pressure and horizontal sheer generated by the hydraulic-pneumatic spring loading system. Owing to the relative velocity between the table and the rollers, the grinding track is divided into compress grinding zone and friction grinding zone.

-

Hydraulic elastic loading system

According to the material properties and the fineness and output requirements of the finished product, the hydraulic loading force and the clearance between the grinding roller and the grinding plate can be adjusted within a certain range, and these factors have been fully considered in the design of the hydraulic elastic loading system.

Hydraulic elastic loading system includes: hydraulic cylinder, piston rod, accumulator, high pressure oil station, valve and control circuit. Each hydraulic cylinder is equipped with an accumulator with sufficient volume to keep the grinding pressure stable and ensure the smooth operation of the mill and the service life of the hydraulic loading system.

Since the roller can be turned out by the hydraulic elastic loading system, it is very convenient to repair the grinding roller device.

-

Grinding roller and table

Roller sleeve is designed with spherical surface, and the lining plate of grinding disc is also of spherical groove structure, which forms a uniform grinding gap between the grinding roller and the grinding plate in the circumferential direction of the grinding disc. There is no metal contact between the grinding roller and the grinding plate due to the mechanical buffer when the grinding plate is empty or feeding.

Retaining ring designed with proprietary technology can increase the contact uniformity between the roller surface and the material, which is conducive to grinding.

Roller sleeve and lining plate are made of high chromium alloy material with excellent wear resistance, and this material is suitable for surfacing welding. The mobile welding equipment can be used to repair local wear and prolong the service life.

Lubrication of roller bearing adopts centralized thin oil lubrication station to filter and cool the lubricating oil, and supplies equal amount of oil to each grinding roller through distributor.

-

Nozzle ring

The flue gas from conveying and drying materials enters the mill through the air ring. The shape and geometric size of the air ring determine the gas flow distribution and velocity in the mill.

-

Drive system

The driving device is composed of motor, coupling and reducer. When starting the mill, the grinding roller can be lifted by the hydraulic cylinder. No matter with or without material, the mill can be started with light load without auxiliary starting device.

he reducer adopts a reliable bevel gear planetary gear structure. The axial thrust bearing supporting the grinding plate and grinding pressure is designed with multiple pieces. The thrust pads are immersed in the oil pool, and the lubricating oil is cooled and filtered through the lubrication station.

-

Separator

The driving device is composed of motor, coupling and reducer. When starting the mill, the grinding roller can be lifted by the hydraulic cylinder. No matter with or without material, the mill can be started with light load without auxiliary starting device.

he reducer adopts a reliable bevel gear planetary gear structure. The axial thrust bearing supporting the grinding plate and grinding pressure is designed with multiple pieces. The thrust pads are immersed in the oil pool, and the lubricating oil is cooled and filtered through the lubrication station.

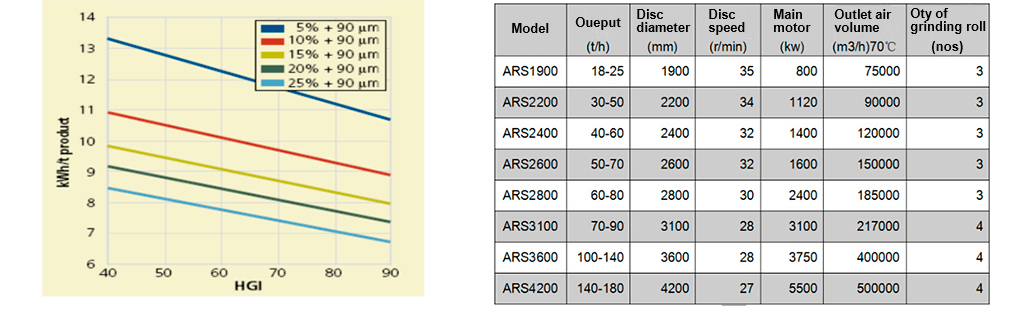

The rated output of the mill is determined by the grindability of the material, the required product fineness, water content and system operating conditions (such as the temperature of dry gas, air volume, etc.).

The grindability is usually specified according to the Hardgrove Grindability Index (HGI). The energy consumption of an ANDE mill depends on the grindability of the material and the product fineness, which is shown in the grindability diagram. Throughput of same mill size for different materials may vary greatly.

Mill model: ARM + material English code + mill plate medium diameter- roller quantity

Material English Code: Coal - no "material English Code"

Granulated blast furnace slag – s

Cement clinker – C

For example: ARM19-2, coal mill, medium diameter of grinding plate, 1900mm, two sets of grinding roller

Arms26-3, slag mill, medium diameter of grinding plate 2600 mm, 3 sets of grinding roller

LinkedIn

LinkedIn Twitter

Twitter Facebook

Facebook Instagram

Instagram YouTube

YouTube