1 Brief introduction of pulverized coal

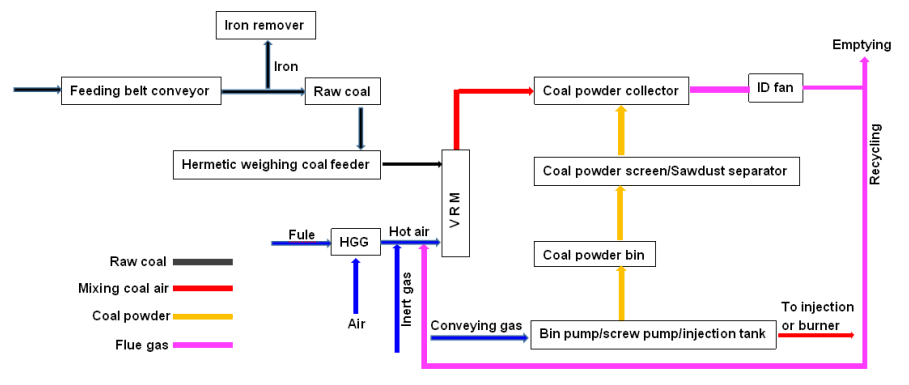

Grinding system made the raw coal to be qualified coal powder, use the vertical mill as its core, and dried the coal powder in the process of grinding.

2 Main characteristics

Using the vertical mill as the core, the short technological process of one class of high concentration pulverized coal collector.

Grinding and drying integrated, wide adaptability of coal, drying ability is strong, the fineness of pulverized coal can be arbitrary regulate.

Energy saving, power consumption of per ton coal is less than or equal to 28kwh

Equipped with three levels of explosion-proof measures, ensure the system operation safe and stable.

Using gas self circulation process, further saving energy

3 Process flow

4 Brief introduction of each sub system

4.1 Feeding system

Using large tilt angle belt machine or lifting machine to feed

Equipped with iron remover

4.2 Drying gas system

Using flue gas generating furnace, gas, coal and other various fuels

Supplement inert air or exhaust gas of system, reduce the flue gas temperature and oxygen content.

4.3 Grinding system

Using closed quantitative coal feeder to feed material, good sealing performance, uniform feeding.

Using vertical mill to integrate grinding and drying in one, with a dynamic / static separator, pulverized coal fineness can conveniently adjust.

4.4 Collecting system

Use one grade high concentration coal powder collector, electromagnetic pulse valve cleaning, the cloth bag is waterproof, oil proof and anti-static needle felt, with explosion relief valve

Using high pressure fan full negative pressure pulverizing, good working environment, no leakage of coal powder.

4.5 Power Supply and Distribution

All low voltage electrical equipment equipped with short-circuit protection, low-voltage motor equipped with overload, short circuit, pressure loss and phase failure protection.

AC motor need speed adjusting adopts AC frequency conversion drive device

Modes of operation: Manual (maintenance, debugging), emergency manual, automatic PLC and manual PLC four control modes

4.6 Automation system

Grinding production process using the automation system of EIC control range, including the detection and control of raw coal system, grinding system, transportation system and other auxiliary system.

Considered in the design and selection of automation system as follows: full system reliability, operability of the system, system maintenance, system openness, and system expansibility.

4.7 Instrument configuration

The selection of the instrument is mainly considered the factor of the safety,reliably, price performance, operation and convenient maintenance and etc. to meet the requirement of dust explosion environment. Instrument signal used the standard 4 ~ 20mA signal, analog signal added separator to carry on the electrical isolation. Analog input and output adopts 4 to 20mADC.

5 Explosion proof measures

Uses three levels of explosion-proof control measures, to ensure that the operation of the system is safe, stable.

One-level of explosion-proof: limit the formation of coal dust explosion conditions, control temperature, control oxygen, control concentration.

Two-level of explosion-proof: prevent blasting explosion-proof air ignition, ventilation of grinding system, reliable grounding of electrical equipment, select explosive proof grade of electrical equipment according to the explosion proof area.

Three-level of explosion-proof: limit the explosion consequences in minimum damage or harmless, the flue gas furnace, mill, coal powder collector, coal storehouse and etc. equipped with explosion-proof valve.

LinkedIn

LinkedIn Twitter

Twitter Facebook

Facebook Instagram

Instagram YouTube

YouTube